Phosphate, parkerization, US regulatory formula.

Manual :

The parts to be phosphated will be cleaned to white, without being polished, a sandy finish for example is very advisable.

Parts will be very carefully degreased (tri-chlorine, degreaser, etc ...)

Avoid touching parts with your fingers (eg rubber gloves)

Put the dose into a metal container of a shape suitable for the parts to be phosphated, which will only be used for this purpose (an unglazed iron container and especially not aluminum).

Very important :

- Put all the contents of the bottle so that the dose is complete (deposit may have formed at the bottom of the bottle).

- To do so, it is necessary to shake the bottle so that the deposit found is well used with the entire content of the dose.

- Add 5 liters of distilled water (or, if necessary, rainwater).

- Provide a small metal box pierced with holes with a handle for small parts and screws.

Phosphating is carried out by boiling the parts to be treated for a period that may vary from half an hour to 4 hours.

We check the color (black gray) by removing the pieces from time to time.

When the appearance is obtained, rinse the parts with water and cover them with petroleum jelly, flax or encaustic.

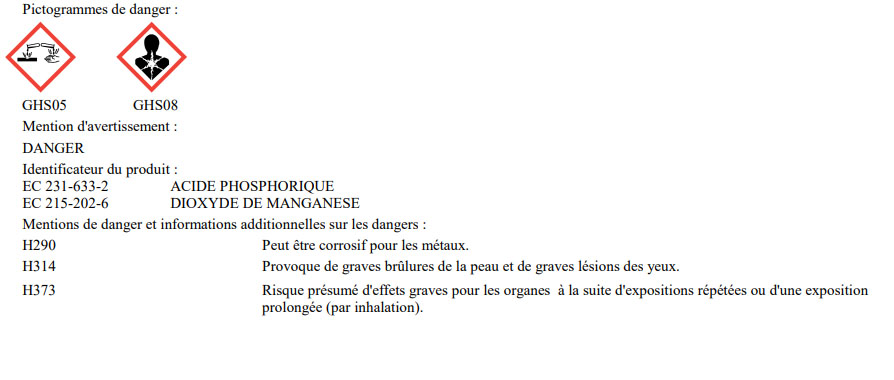

Dangerous - Respect precautions

Download here the SDS