Manual :

The parts to be blackened must be "polished" and perfectly degreased. If necessary, repolish the metal.

- Degrease generously with the degreasing solvent.

- Spread the product using an arquebuserie wick plug (0000) lightly impregnated with liquor.

Avoid casting.

- Go back to the parts already treated.

- Leave to dry for several hours (1 night for the first coat).

Then card (rub with steel wool until the marbling or oxidation dust has completely disappeared).

- Apply the solvent with a bit of wick, insisting on removing any impurity.

- Rub with a dry wick.

Repeat the operation several times (between 4 and 8 times), until the desired black is obtained

After the last coat, rinse with clean water then dry well by rubbing with a wick pad.

Then apply a light coat of finishing product (with a wick pad) for a shiny finish, do not rub too much.

Precautions and recommendations:

The steels used for the different parts of a weapon are not the same. Shades can therefore appear.

Depending on the quality and amount of carbon in the steels, the tan can sometimes show mottling.

Before starting the operation on your final piece, we advise you to carry out tests in order to determine the desired tone and to "get started".

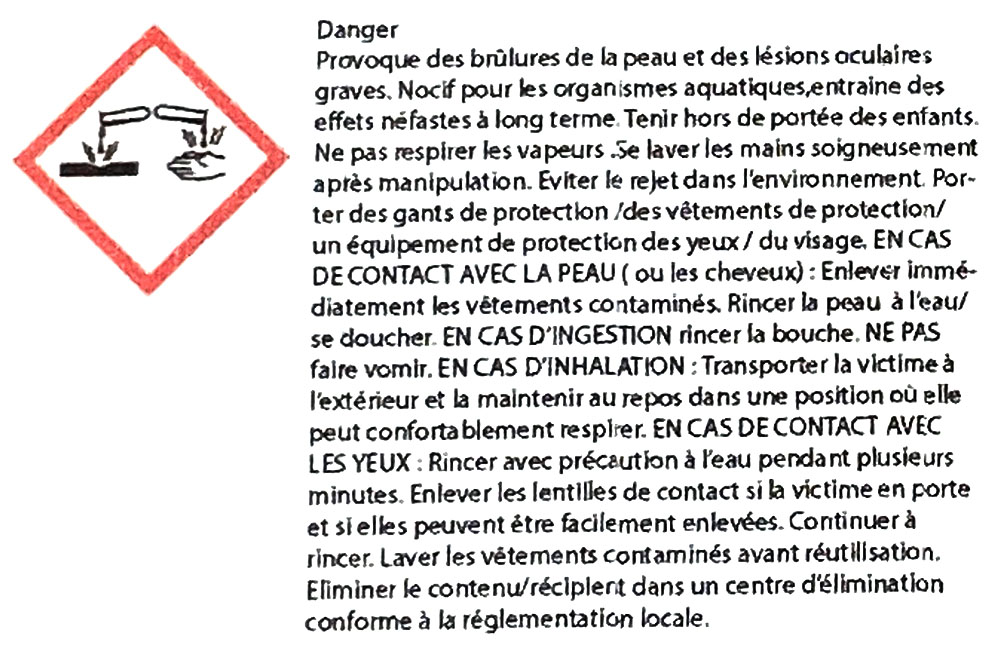

Dangerous - respect precautions

Download here the SDS